FOREWORD

to the reprinting of

“Lead-rubber hysteretic bearings suitable...”

Once upon a time — well, actually, April

1970 — in a New Zealand tea room, Bill met Ivan... and that

was where this particular adventure in seismic isolation

began.

Bill — Dr. Bill Robinson — and Ivan—

Dr. Ivan Skinner — were both members of New Zealand's

Department of Scientific and Industrial Research, and the tea

room in question was part of its Physics and Engineering

Laboratory (PEL) on the Gracefield Campus near Wellington.

Ivan, head of Engineering Seismology, had briefly returned to

New Zealand from a sabbatical in Japan, and told Bill of how

he proposed to use steel dampers in the seismic isolation of

the new design office being planned for New Zealand's

Ministry of Works (MOW), known as the William Clayton

Building.

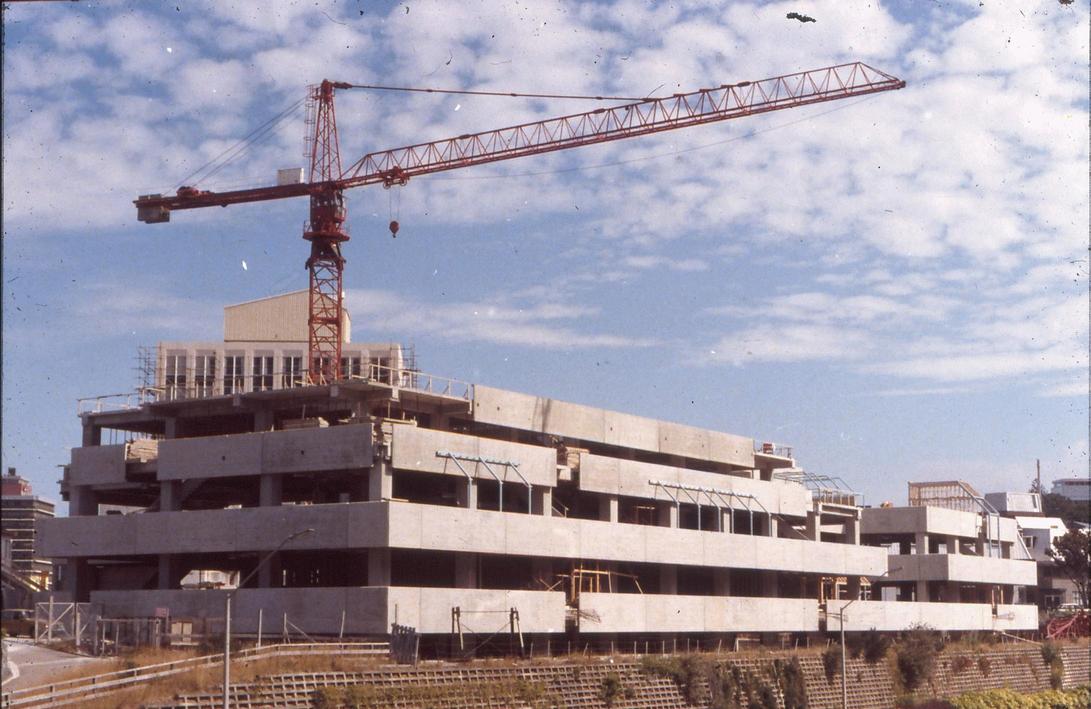

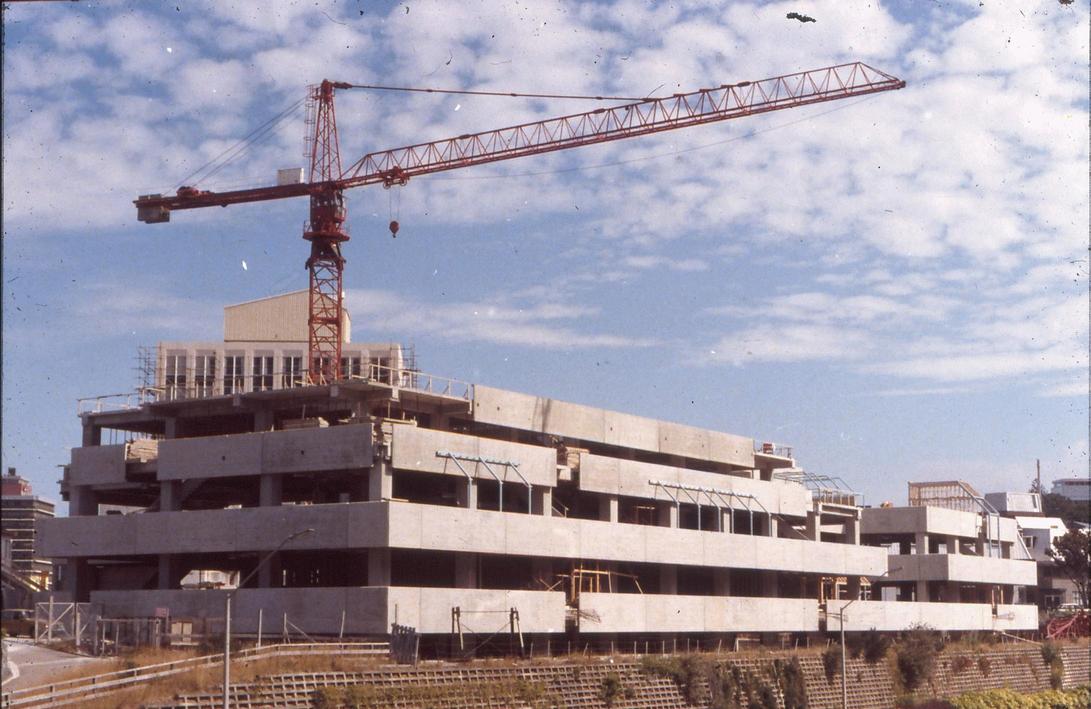

William Clayton Building under construction, 1981.

Bill thought he could find a better

material for damping than steel, so he went back to his

office and spent the next two hours looking carefully for an

element that had a relatively low melting point (∼300°C), was

face-center cubic (fcc), was readily available at a high

purity (impurities ≤100 ppm) — and all at a reasonable

price. The only element that met these demands was lead. Its

relatively low melting point ensured that any plastic

deformation would be healed at room temperature by the

interrelated processes of recovery, recrystallisation and

grain growth, while its fcc meant there would always be a

slip system available to accommodate any deformation and its

high purity would see to it that the plastic deformation

could be maintained and results would be consistent.

The next problem was how to deform lead

so that a relatively large damping force of 1 to 100 tonnes

could be produced. The solution was a lead extrusion damper

(LED). This thinking culminated in twenty-four 25 tonne LEDs

(±400 mm) being manufactured and tested by PEL to

provide the damping for seismically isolating the Wellington

Central Police Station. This 10-storey tower block is

supported on long piles in caissons founded 15m below ground

in weathered greywacke rock. The near surface-soil layer

consisted of marine sediment and fill of dubious quality.

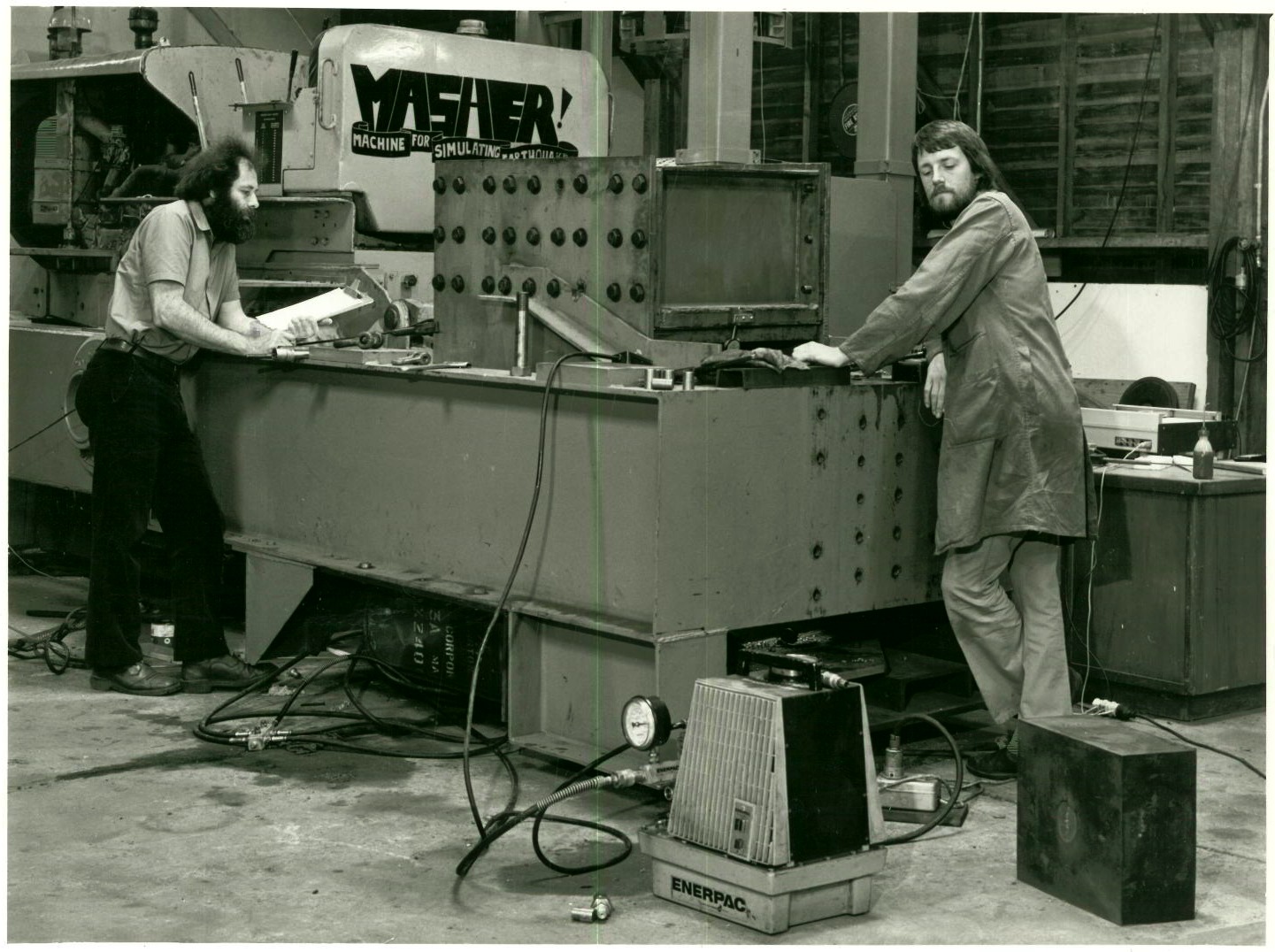

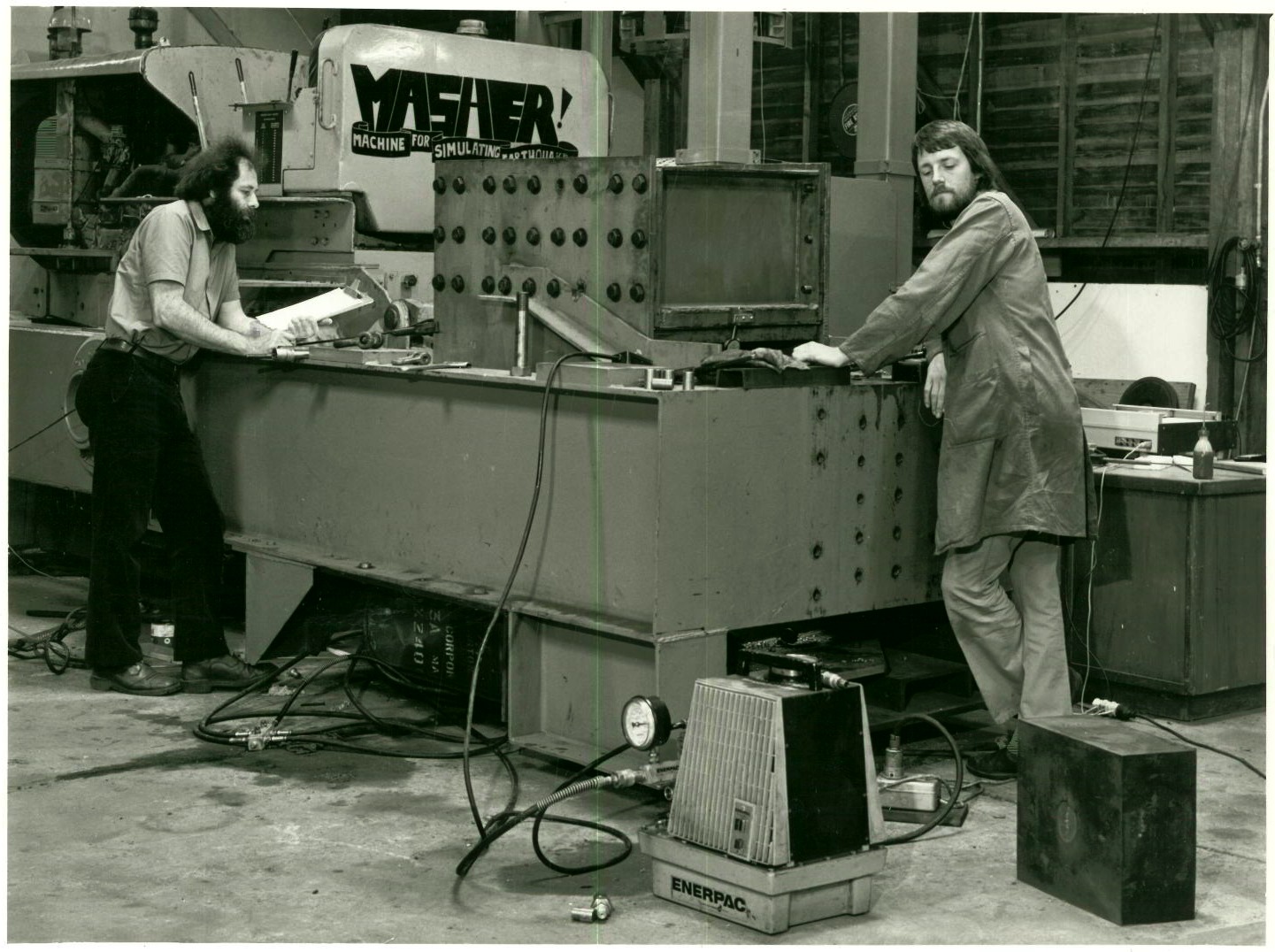

Bill and his technician Alan Tucker operating the MASHER.

The LED, however, was not an elegant

solution for damping the MOW's William Clayton Building, so

instead Bill started trying to make a lead shear damper. But,

no matter what the shape, they always failed after one

quarter of a cycle. Obviously they needed to be supported in

some way. As recorded in Bill's lab book, the solution, which

occurred to him at home on 2 April 1975, was to place a lead

plug through the layers of steel and rubber. It was not until

April 1977, though, that his team was able to obtain two

cemented laminated rubber bearings from the Engineering

Seismology Section, have the workshop drill a 56mm diameter

hole in one, press a lead plug in the hole, and test both in

an Instron testing machine.

The results were so promising that Bill

immediately contacted the MOW engineers working on the design

of the William Clayton building and they decided to sell PEL

an old D8 Caterpillar tractor to use as the basis of a test

machine. PEL sold the tractor's blade for more than the cost

of the tractor itself and the engineering design team, led by

Cam Smart, designed a rig powered by the >100 KW

diesel engine, capable of providing a vertical load of 300

tonnes and a displacement of up to 91 mm. Bill then

tested a series of bearings of progressively increasing

diameter, until at a lead diameter of 170 mm, after two

cycles the gearbox failed! This result was viewed by all as a

success and enabled the project to proceed. Today thousands

of buildings and bridges worldwide use the lead-rubber

bearing.

References

[Kelly et al. 2011] T. E. Kelly, R. I.

Skinner, and W. H. Robinson,

Seismic isolation for designers and structural

engineers, Robinson Seismic Ltd., Petone, New

Zealand, 2011.

[Skinner et al. 2003] R. I. Skinner, W.

H. Robinson, and G. H. McVerry, An introduction to seismic

isolation, Wiley, New York, 2003.

Bill and his colleague, Dr. Michael Staines, on the

sea ice at Tent Island, McMurdo Sound, Antarctica, near

Scott Base. The final version of the paper reprinted on the

next few pages was written while Bill was a research fellow

at Scott Polar Research Institute, Cambridge, England

learning about sea ice.

|